Automated Storage and Retrieval Systems (ASRS) help warehouses by greatly reducing the need for human pickers, which, in turn, allows business owners a range of benefits.

These benefits include increased shelving density (since no aisle space would be required for a human picker) and reduced labour costs. Our guide explains how ASRS can transform SME warehouses, the different types of ASRS, and how business owners can get started setting up their own ASRS for their warehouse.

Key Takeaways

- Space optimisation is a major advantage, as ASRS solutions eliminate the need for aisle spacing, thereby increasing storage density and capacity.

- Different ASRS types suit different needs. Unit-load systems are ideal for pallets and bulk items, whereas mini-load systems are ideal for small containers and high SKU counts, for example.

- ASRS solutions can integrate with warehouse management systems, enabling real-time tracking of stored items and sales.

- SMEs benefit from scalable solutions that can grow with the business, whether adding shuttle systems, vertical carousels, or additional racks.

- Automated warehouse systems reduce human error, greatly reducing instances of customers receiving the wrong orders.

What are Automated Storage and Retrieval Systems (ASRS)?

ASRS are computer-controlled solutions designed to store and retrieve items from warehouse shelving.

These systems use storage racks, carrier devices, and inventory management software to retrieve items from their shelves. This means that picking will primarily rely on cranes, shuttles, conveyors, or similar automated devices to retrieve items for packing. The result: less reliance on human pickers.

ASRS software is also integrated with the business Warehouse Management System (WMS), enabling warehouse managers to monitor inventory in real-time. This allows for a smoother warehouse workflow and provides managers with a more accurate inventory forecast.

Key Benefits of ASRS for SME Warehouses

ASRS solutions bring tangible benefits to warehouses of any size.

- Space optimisation: Automated systems use vertical space, allowing high-density storage that maximises horizontal floor layouts.

- Faster retrieval: Storage and retrieval machines bring items directly to the operator, minimising travel time across the warehouse.

- Accurate inventory management: Defined storage locations and computer-controlled retrieval reduce errors and improve inventory control.

- Reduced labour costs: Automated warehouse systems decrease reliance on manual picking, freeing staff for other material handling processes.

- Scalable solutions: ASRS solutions can grow with your business, adding vertical lift modules, shuttle systems, or additional storage racks as needed.

- Improved safety: Repetitive tasks and heavy pallet handling are handled by machines, reducing workplace injuries.

Key Parts of an ASRS

Carrier Device

The carrier device is the heart of any automated storage and retrieval system. It moves items between storage locations and access points. It can be a retrieval machine, shuttle, or robotic system, depending on the ASRS type.

Storage and Racks

Storage racks form the framework of the ASRS. They can be shelving racks, mobile shelving, or high-rise pallet storage. They store items until the carrier device moves them to another location.

Control Software

The control software is the brain of the ASRS. From this console, workers operate the ASRS to retrieve and store items and manage inventory. The control software also integrates with existing WMS to maintain accurate inventory and sales reporting.

Types of ASRS for SME Warehouses

Vertical Lift Modules (VLMs)

Vertical lift modules are vertically built ASRS that utilise a vertical-moving carrier device to retrieve items from their shelves. Using a belt drive, the carrier device picks items from densely-packed shelving and brings them to the operator at a comfortable height.

Because they’re built vertically, VLMs occupy a small horizontal footprint. This makes VLMs ideal for warehouses with limited space, as they utilise vertical space to maximise storage capacity. These machines don’t require separately-bought shelves; they already come with their own shelving and carrier device in a compact housing.

These systems reduce the risk of injury since workers won’t need ladders—the machines bring items to pickers at waist height.

VLMs also come with a console that operates the machine. Through these consoles, workers can manage and track inventory for proper record-keeping.

Vertical Carousel Modules

Also known as carousel machines, these machines function like a Ferris wheel. Shelves rotate on a belt, carrying with them their respective SKUs. At the press of a button, the belt rotates until the machine brings the workers’ desired item to the window for them to take and pack. This eliminates the need for workers to search through traditional shelves, reducing the risk of falls and injury.

Though they’re similar to VLMs in that they’re optimised vertically, they’re different from VLMs in terms of mechanism. While VLMs use a belt drive, similar to an elevator, carousel machines are more similar to Ferris wheels. They rotate all the shelves until the right shelf presents itself through the window.

Due to their compact designs, these vertical systems are ideal for warehouses of any size. Business owners may acquire a single carousel machine or VLM before fully committing to full-scale warehouse automation, such as the options below:

Unit-Load ASRS

These systems use a storage and retrieval machine that travels along fixed aisles to move pallets in and out of high-rise storage racks. They are ideal for distribution centres and warehouses with large footprints.

Unit-load ASRS mainly operates with pallets and heavy loads, which are especially useful for manufacturing plants that cater to wholesalers and retailers.

Mini-Load ASRS

A Mini-load ASRS functions similarly to Unit-load ASRS, utilising cranes and conveyor belts, but is designed for small containers, totes, and cartons.

These systems are ideal for warehouses handling a wide variety of SKUs, including e-commerce fulfilment centres, pharmaceuticals, cosmetics, and spare parts facilities, among many other industries that rely on small goods.

Pallet Shuttle ASRS

A pallet shuttle ASRS is a robotic system that utilises automated shuttle vehicles to move pallets horizontally within deep storage racks. They’re ideal solutions for warehouses with a large horizontal footprint. Businesses may need a pallet shuttle ASRS when the time it takes to walk from one end of the warehouse to the other significantly impacts productivity and profits.

Cube-based ASRS

Cube-based ASRS involves picker robots moving across a cube-shaped infrastructure to store and retrieve items. The cube-shaped shelving (hence the name) offers the most compact storage possible, as it leaves no aisle for humans to walk through.

Robots run along the cube’s grid and retrieve, rearrange, and store bins. Because of this, a cube-based ASRS is one of the more complex systems on this list.

Floor robots

Floor robots, also known as autonomous mobile robots (AMRs), are designed to transport goods throughout a warehouse without relying on fixed aisles or tracks. They navigate the warehouse floor using sensors, carrying pallets, bins, or totes between storage areas and packing stations.

Implementing ASRS for Your Warehouse

Assess Your Warehouse Space

Measure available floor space and ceiling height. Understanding vertical and horizontal space helps determine which ASRS solution suits your warehouse.

Assess Your Throughput

Analyse how many items your warehouse needs to store and retrieve daily. This guides the choice between unit-load, mini-load, shuttle systems, vertical lift modules, or deciding whether you need an ASRS outright.

Assess Your Load Units

Identify the types of loads you handle. The types of loads you’ll store will determine the design of your storage racks, shelving systems, and carrier devices.

Get in Touch with an ASRS Provider

A reliable provider can advise on space optimisation, automated solutions, and the best material handling equipment for your operations. They can tailor a solution that integrates conveyor systems, automated guided vehicles, or robotic systems with your existing WMS.

Implement ASRS for Your Warehouse Today!

ASRS transforms warehouse operations from human-run facilities into automated plants that can run 24/7.

They maximise storage density, reduce labour costs, and improve inventory management. SME warehouses in Singapore can benefit from these modular solutions, enabling their businesses to scale as storage demand increases.

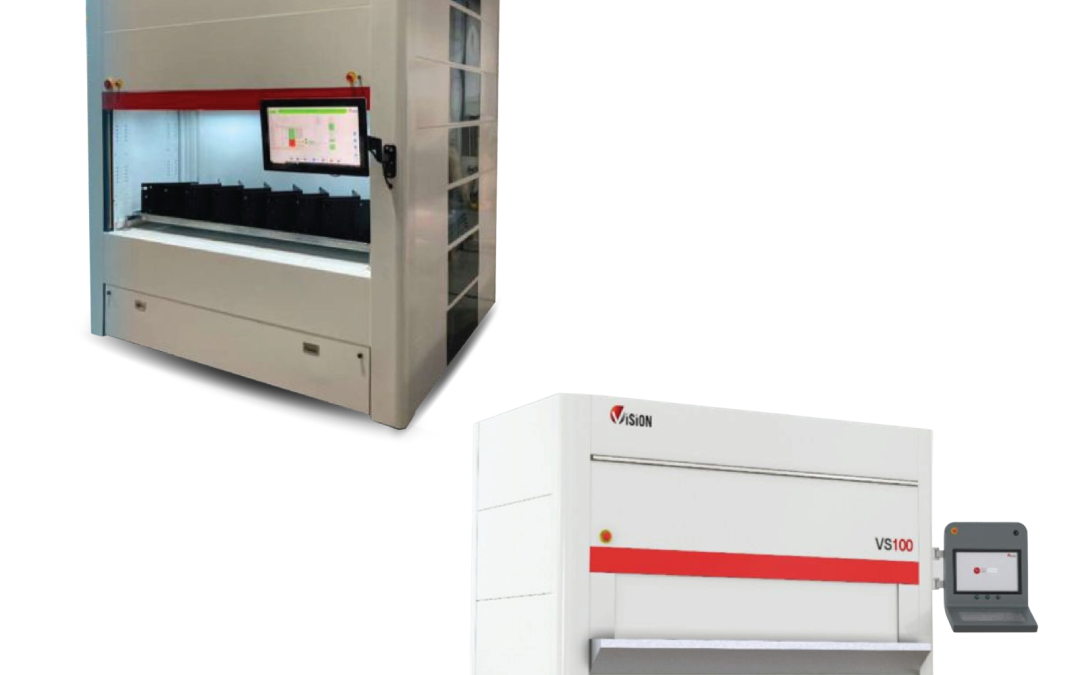

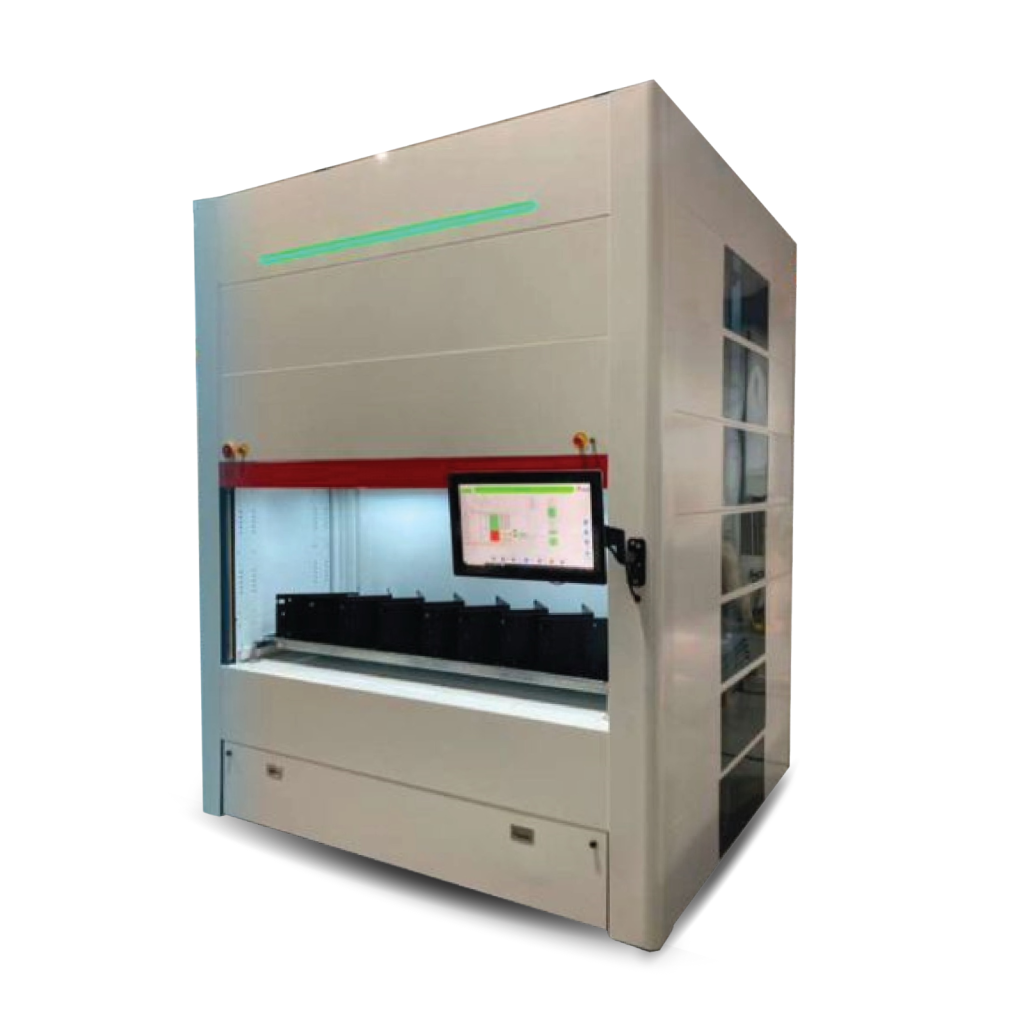

Vision IoT’s Vertical Storage Systems provide warehouses with automated functionality without the massive upfront investment. Included with our vertical storage solutions is a control module that enables single-person operation of the machinery and supports crucial inventory management.

Get in touch with Vision IoT today to learn more about our vertical storage systems.

Frequently Asked Questions (FAQs)

What types of items can ASRS handle?

ASRS solutions can handle a wide range of items, from pallet loads in manufacturing to small totes, cartons, and bins in e-commerce and spare parts storage. The choice of system depends on item size, weight, and storage density requirements.

Can ASRS fit in small SME warehouses?

Yes. Mini-load systems, vertical lift modules, and vertical carousels are designed for space-constrained warehouses. They optimise vertical and horizontal space, maximising storage capacity without expanding floor space.

Are ASRS solutions scalable?

Yes. Most ASRS solutions can expand by adding shuttle systems, storage racks, vertical lift modules, or robotic systems. This allows SMEs to scale storage capacity and automation as the business grows.

Do ASRS solutions reduce labour costs?

Yes. By automating repetitive tasks, retrieval, and pallet handling, ASRS reduces reliance on manual labour. Staff can focus on value-added material handling processes rather than routine picking.