When it comes to scaling eCommerce, storage space can quickly run out as you try to keep up with demand. However, expanding the warehouse floor area is an expensive move, especially for SMEs.

A vertical carousel storage system offers an alternative. It utilises vertical space to maximise storage and make the most out of the warehouse’s horizontal layout. Many SMEs now consider automated storage solutions because, in addition to maximising space, they also reduce labour costs and improve inventory management.

In this guide we’ll explain what a vertical carousel storage system is and how SMEs can benefit from it.

Key Takeaways

- A vertical carousel storage system helps SMEs optimise space by using vertical space instead of floor space.

- Faster retrieval shortens picking time and helps eCommerce teams handle more orders.

- The storage system reduces labour overhead because operators do not need to climb ladders or rummage through boxes.

- Inventory accuracy improves because every stored item is tracked through software integration.

- Warehouse safety improves because vertical carousel storage’s design eliminates hazards associated with manual shelving.

- Vertical carousel systems increase storage density, utilising the warehouse to its fullest.

What is a Vertical Carousel Storage System

A vertical carousel storage system is a vertically optimised machine that enables warehouses to maximise storage capacity by utilising available vertical space. It’s an ideal solution for warehouses with minimal horizontal space.

Unlike shelves, which leave a lot of empty space, vertical storage systems are densely packed. They are designed to carry a lot of weight in each tray, allowing warehouses to store as many items in each of these machines as their volume allows.

How it Works

A vertical carousel storage system (VCM) works like a Ferris wheel. The system rotates individual trays up and down to bring one tray to the operator’s access point. This creates a compact vertical storage unit with a relatively small footprint.

The operator does not need to climb ladders or walk through long aisles. The system presents the stored items to the user at a safe and comfortable height.

Compared to many large-scale ASRS solutions that require full-scale warehouse automation VCM systems are ideal because they don’t require an upfront investment in robust infrastructure. Businesses can start with only one unit of our vertical storage system without committing to purchasing other parts and components.

Our VCM system features a control console that enables employees to manage and track inventory.

Benefits of a Vertical Carousel Storage System for Warehouses

Maximised Space for Warehouses

A VCM system enables SME warehouses to utilise available space more efficiently.

It uses vertical space instead of floor space. This results in a higher storage density compared to traditional shelving. Operators can store more stock in a smaller horizontal footprint, utilising the full layout of the warehouse.

Furthermore, businesses that need to optimise space often find that vertical storage reduces the need for expansion. That’s because, instead of leasing more warehouses, businesses can simply add additional vertical carousel units using the same floor space, rather than leasing more warehouse area. This means building vertically rather than horizontally. Facilities with a high ceiling height gain the most from this setup.

Faster Picking Process for eCommerce Businesses

VCM systems help e-commerce fulfilment teams improve efficiency. The carousel rotates the trays internally, providing the operator with quick access to the correct tray. This reduces item retrieval time, enabling faster order fulfilment.

Operators do not need to search multiple racks or walk across long aisles. A warehouse equipped with a carousel storage system experiences less congestion.

Better Efficiency / Reduced Labour Cost

Each vertical carousel machine is a picker in its own right. Give it an instruction to retrieve an SKU, and it will bring that SKU to the operator, just like a human picker. As a result, integrating VCMs into the warehouse’s operations improves efficiency and productivity, enabling businesses to fulfil more orders on any given day.

Also, having carousel machines reduces reliance on human pickers, which, in turn, reduces the labour overhead required to maintain a smooth order fulfilment process.

Built-in Software and Easy Integration

Most automated storage systems can integrate with a warehouse management system (WMS), and vertical carousels are no different. The advantage for SMEs is that they reduce menial tasks for warehouse staff and ensure inventory accuracy.

Vision IoT’s vertical carousel already includes its own storage management software and touchscreen console, so warehouse staff have easy access to the WMS while operating the machine.

This gives you real-time stock visibility and transaction history, and it ensures an ergonomic workflow for your staff. Data flows automatically between the carousel and your other warehouse processes.

Improved Inventory Accuracy

A VCM system improves inventory management because all stored items are tracked. The system knows which tray holds each SKU. Operators rely less on manual search, so the risk of misplacement is lower.

The system can record every retrieval and return, so the stock view stays updated. This works well for SKUs with high movement rates.

Improved Warehouse Safety

Warehouse safety improves when operators no longer need to climb ladders or reach high shelves. Many injuries come from falls or strain from lifting. A VCM system reduces these risks because the system handles all the retrieving.

At the push of a button, Vision IoT’s carousel machines deliver items to waist height, allowing warehouse staff to simply pick them up. The result is a safer environment and a more stable workflow.

How to Set Up a Vertical Carousel Storage System

Assess your Warehouse Space

Start by assessing the floor space and ceiling height of your warehouse. A VCM system works best when there is enough vertical space. Check whether the unit installation fits your layout.

Many carousels come with a relatively small footprint, so in most scenarios, installing one in your warehouse shouldn’t be a concern. However, you’d still want to ensure that your warehouse’s space aligns with the carousel unit’s dimensions. Assessing the available space helps you plan the right carousel model and configuration.

Assess your Load Units

Depending on the manufacturer and model, carousel trays are typically can handle from around 200 kg to 500 kg per tray, with some heavy-duty systems rated higher. Always check the tray load capacity and compare it with your stock weight. Doing so will reduce the need for repair and maintenance.

Get in Touch with an ASRS Provider

Contact an experienced ASRS provider once you know your needs. The provider can guide you through installation costs, purchase price, module and maintenance costs. Cost differences vary based on height, tray count, software features, and energy consumption.

A good ASRS provider will also help you estimate the total cost of ownership. This covers upfront costs, software setup, unit installation, and long-term maintenance. SMEs benefit from choosing an adaptable solution that can scale with future demand.

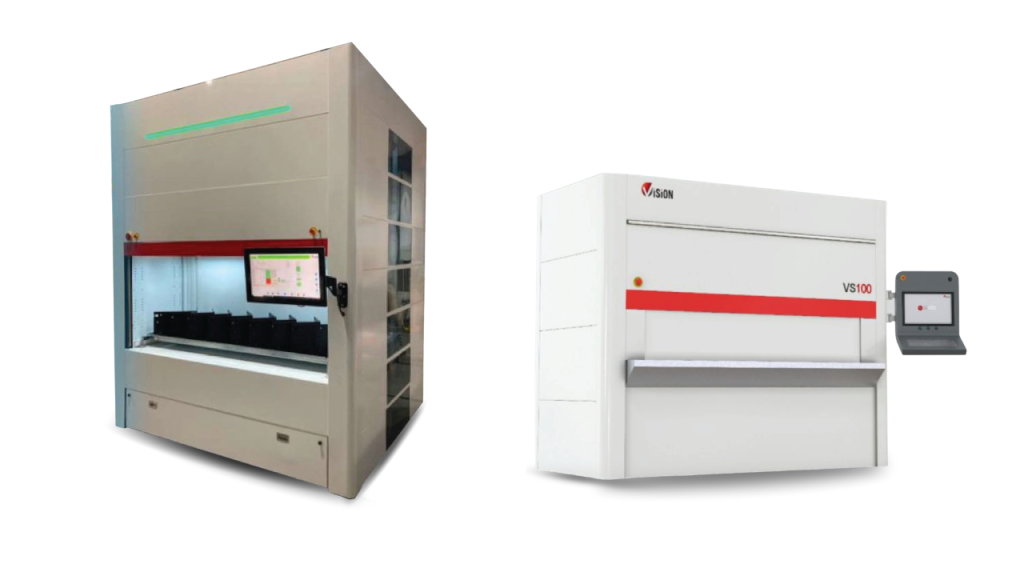

Meet Vision IoT’s Vertical Carousel Storage System

For SMEs who want the benefits of automated storage without a full warehouse overhaul, our vertical carousel offers a compact, ready-to-use solution.

- Small footprint, big capacity: Our standard unit stands about 2.25 m high, has a compact footprint, and accommodates 10 trays (approx. 2000 × 380 × 290 mm each), with a total payload of up to 2,500 kg. This lets you store more items in a given floor space by making full use of your facility’s height.

- High tray load capacity: Each tray is rated for up to 250 kg, so you can safely store small to medium-weight items, spare parts, and components without overloading the system.

- Smart tray organisation: We allow you to divide trays with partitions so that you can group items by SKU, work order, or category. This makes it easier for your team to find what they need quickly and maintain clear stock visibility.

- Built-in OptiFlex touchscreen control: Our 19″ industrial touchscreen with OptiFlex software lets operators call up items, view tray contents, and confirm transactions through an interface that feels as intuitive as a modern smartphone.

- Real-time stock overview with Vision Store Manager: With our storage management software, you get a live view of what’s stored in each machine and tray. You can perform stocktakes, adjust quantities, and set alerts for minimum stock levels to support proper inventory management.

- Cloud-ready architecture: Our machines use cloud-based technology to report on stock levels and transactions. They can also connect with a warehouse’s other systems to streamline data transfer and improve warehouse operations.

- Scalable solution: We design our systems so you can start with one carousel and scale up over time.

Together, these features give you a vertical carousel solution that’s powerful enough for industrial use, but simple enough to roll out quickly without committing to a full warehouse automation project from day one.

Implement VCM for your Warehouse Today

Vertical carousel storage systems help SMEs do more with less:

- Maximise space by storing upwards instead of expanding your floor area.

- Speed up picking with goods-to-person retrieval and less walking.

- Improve accuracy with guided picking and real-time stock visibility.

- Support safety and ergonomics by bringing items to a comfortable working height and reducing ladder use.

- Control costs by delaying or avoiding expensive warehouse expansion.

With our vertical carousel storage system, we bring these benefits together in a compact, SME-friendly package — complete with built-in software, intuitive touchscreen control, and a clear path to scale as your business grows.

If you’re looking to reclaim floor space, improve picking performance, and gain better control over your inventory, talk to us about a vertical carousel solution for your warehouse. We’ll work with you to evaluate your space, load requirements, and growth plans, and recommend a configuration that fits both your operations and your budget.

Frequently Asked Questions (FAQs)

How does a vertical carousel storage system work?

It works like a Ferris wheel. Individual trays rotate internally until the system brings one tray to the operator. This reduces walking time and makes the retrieval process faster.

What types of items can be stored in a vertical carousel?

Vertical carousels can store electronics, spare parts, small tools, medical supplies, packaging materials, and many small items. Trays can be adjusted to fit items of different heights.

How does it improve inventory management?

All stored items are tracked through warehouse management software. The system records every retrieval and return. This keeps stock levels accurate and reduces misplacement.

What industries use vertical carousel systems?

Various industries use vertical storage systems. These include eCommerce, aerospace parts, automotive parts, distribution centres, healthcare, hospitality, and electronics.

How does it compare with a vertical lift module?

A vertical lift module uses a lift platform to move trays, while a carousel rotates trays in a loop. A carousel suits stable load profiles and a consistent tray layout. A VLM suits mixed load types that need flexible shelf heights.